CLINCH PRODUCTS

Our goal is to make you successful. Our patented clinch tooling systems are designed to work in your progressive and transfer dies. They install the clinch fasteners into your stamped part as it is being produced. This may sound complex but let us ease your concerns.

Our systems use a simple design and standardized components that makes it a natural part of your process. Read more to learn about what special features we have that set our systems apart from the competition.

No matter which one of our Clinch processes you choose, you will find each produces high-quality products with extreme precision and accuracy.

Our systems use a simple design and standardized components that makes it a natural part of your process. Read more to learn about what special features we have that set our systems apart from the competition.

No matter which one of our Clinch processes you choose, you will find each produces high-quality products with extreme precision and accuracy.

In-Die Insertion Tooling

Inserts a range of fasteners into metal stampings- Clinch Nuts, Studs, Rivets, Bushings, and more at speeds of up to 60 strokes per minute.Quick Changeout Feature:

The Clinch Solutions quick-change connector combines both pneumatic and electrical fittings into a single connection for a simple plug and play operation.

Laser Etched Part Numbers:

Smart numbering system is etched onto each part for easy reordering.

Multiple Fastener Types:

Tooling can be customized to fit any type of self-clinching fastener.

Online Fastener Vision System:

Available as an add-on option, it serves as an online quality control tool.

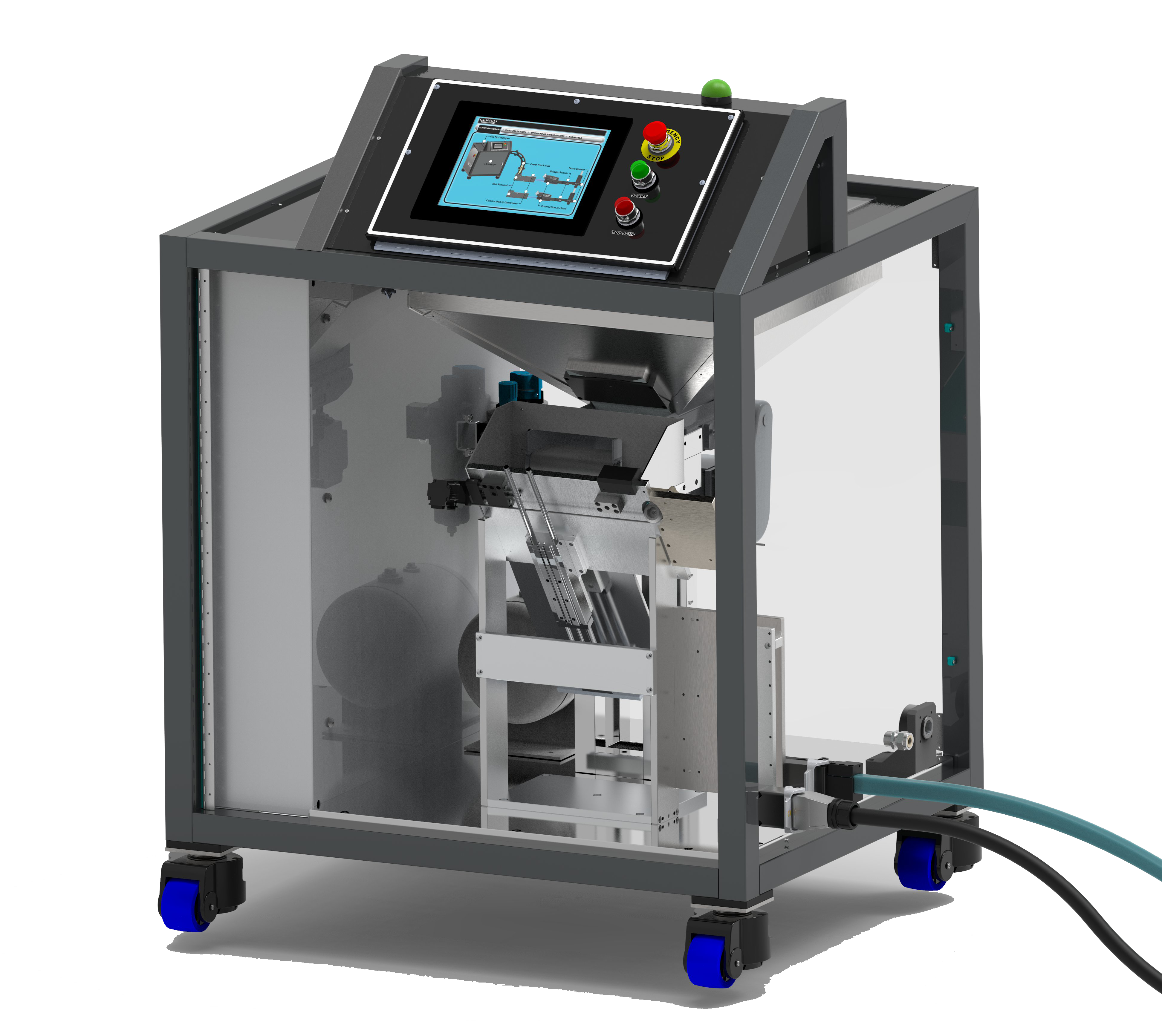

Feed System

Universal Base Design:The feed system features a universal base design that works with many fastener sizes or types, offering flexibility to send your unit back to the factory to have it retrofitted for different needs as pograms end and new ones start up.

Embedded Hopper:

Each unit features an embedded hopper that holds up to 20 times more fasteners than a standard unit. This ensures your feed bowl operates continuously, from the first fastener to the last.

Slide Feeder Technology:

The Clinch Solutions™ slide feeder design is exclusive to our systems. It provides the fastest and most reliable feed system in the industry while staying noticeably quieter than competitors to improve your workspace environment.

User Friendly Interface:

Our large, color touch-screen dashboard lets you monitor the entire clinch process in real-time. With process monitoring at your fingertips, you can make adjustments while the press is running. It also includes maintenance manuals, startup guides, and troubleshooting resources to support new operators.

Durable Welded Frame:

Clinch Solutions™ feed systems are built to withstand the toughest press room conditions. It starts with a 3/4" thick plate supporting the feed hopper systems. This plate is attached to a strong laser welded tubular frame holding the outer shell and components, ensuring a durable and long-lasting design

Spare Parts Inventory

In order to keep your machines running as smooth as possible, we have a large supply of spare parts ready to be shipped to you if needed. By providing a quick delivery of these parts, you can reduce or eliminate the need to have a spare parts inventory yourself.Whether your system is recent or old, we are capable of supplying all the spare parts needed to maintain or repair it. With engraved part numbers on each part, reordering can be fast and simple.

Copyright © 2022 Clinch Solutions, All rights reserved.