12 UNIQUE BENEFITS OF OUR INSERTION TOOLING

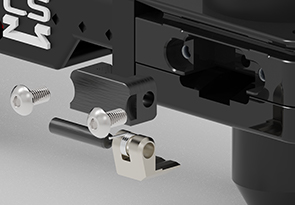

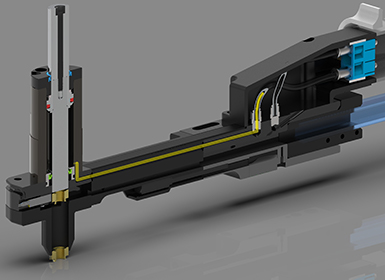

Quick Change Wing Assembly:

The Clinch Solution™ patented design allows the wing details to be removed from the tooling without taking the entire unit apart. This saves valuable press time and can be maintained in the press. Part of our patented design is that we use a tortional spring for maximum performance.

No-Clamp Sensor Wire Holders:

This feature is machined into the head to clamp the sensor wire into a protective pocket. It naturally holds the sensor wire without any fasteners or tools needed.

Composite Sensor Holder:

The composite sensor holder allows the sensor to be held firmly in place without the sensor being exposed to the elements. This protects the sensor nose from ever being adjusted into the fastener. It has a window within the holder to view that the sensor is in the right location.

Carbon Fiber Composite Bridge:

The carbon fiber composite bridge firmly connects the anvil side of the head to the feeder side. This patented design combines features like an embedded sensor, wire covers, embedded air lines and vent holes to extinguish excess air.

Composite Bridge Cover:

This easy snap-in cover allows the sensor wires to be completely contained within the bridge protecting them from being cut or damaged by the elements.

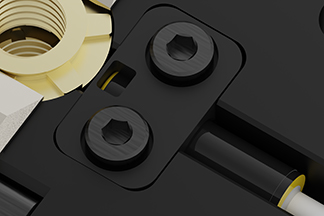

Manifolded No-Snip Airlines:

This benefit allows the air used in this tooling to be manifolded through the internal workings of the entire assembly. This removes the need for external airlines that can be easily cut or broken.

Combined Electrical and Pneumatic Hood:

The Clinch Solutions™ patented design hood allows the end user to quickly change the electric and pneumatic connections in one action. All of these features are stored in the quick change area of the unit.

Low Friction Flexible Shot Tubing:

The low friction shot tubing has grooves designed throughout to allow the nuts to glide thru at a very low friction. This requires less force to drive the fastener into the tooling much quicker.

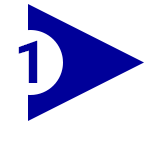

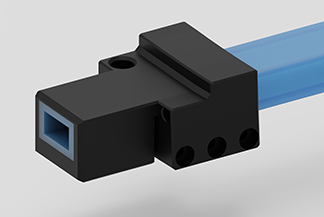

Quick Change One Piece Attachment:

This Clinch Solutions™ feature is a composite 3D printed part that allows the shot tube to be easily attached to both the feeder and fastener tooling using the quick change feature. It has shark bite teeth that when the screws are tightened into the shot tubing, it will grip the tubing and produce a leak-proof attachment.

Safety Sensor for Quick Change Attachment:

This is a safety feature which ensures that the unit will only shoot a clinch component into the tool if the sensor sees the quick change attachment is correctly installed.

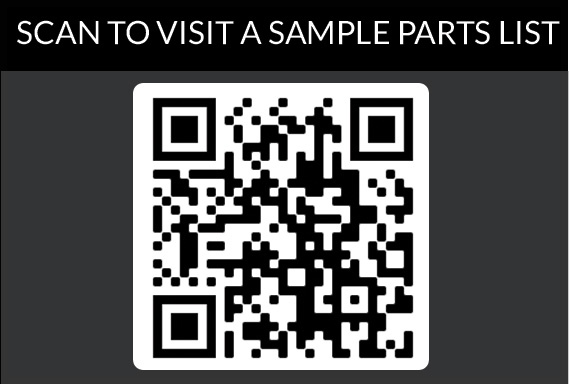

QR Code Bill of Materials:

Every insertion tool has its own unique QR code that allows you to have a full bill of materials and an exploded view of every part of your unit. Use any smart phone to retrieve this information from the backside of our website. This provides you exclusive access to files for your unique unit.

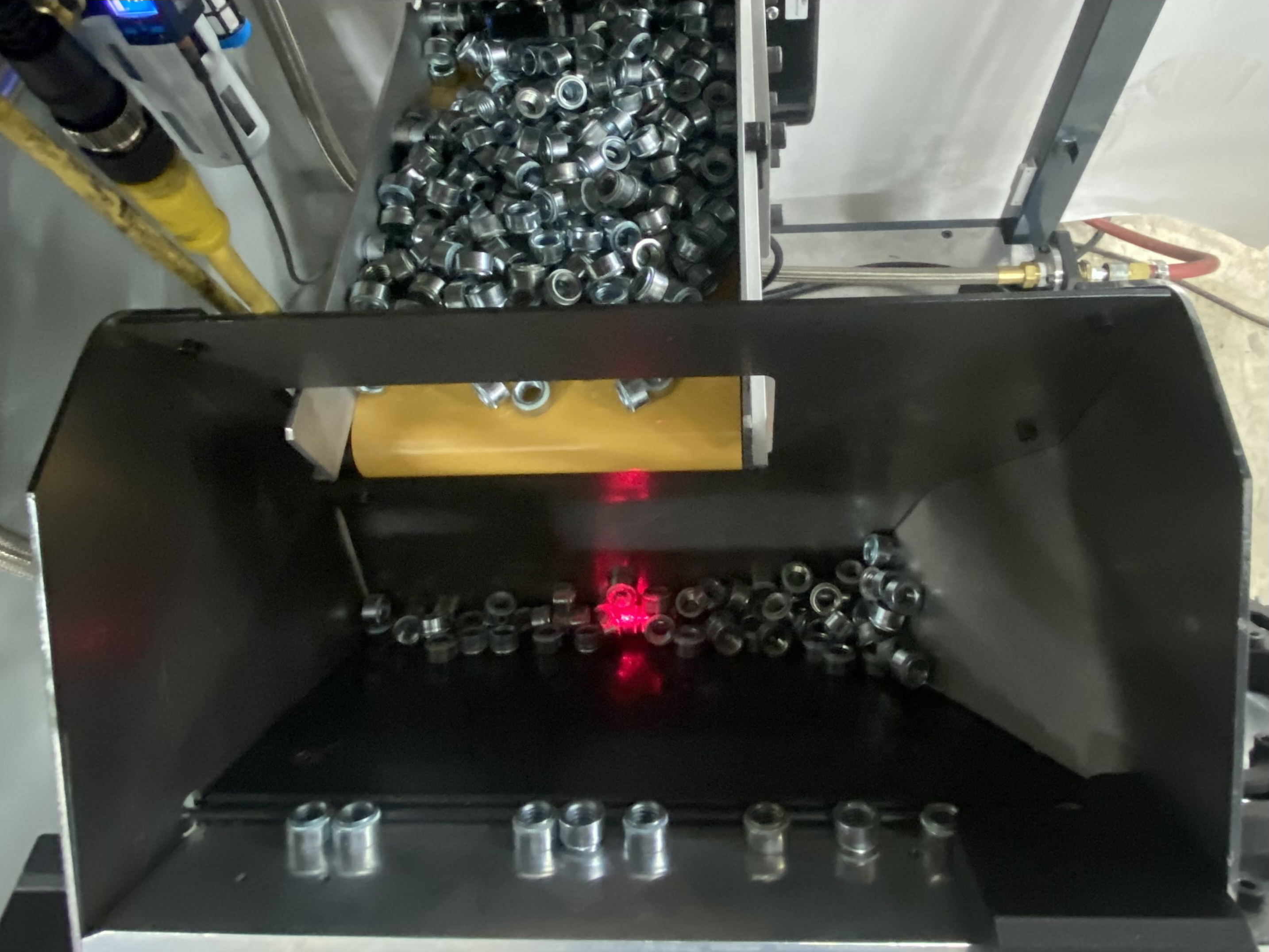

Slide Feeder Technology:

This Clinch Solutions™ slide feeder design is unique to our systems allowing the user to have the fastest and most reliable feed system in the industry. It's also much quieter than our competitors.

Copyright © 2022 Hess Industries, All rights reserved.